![]()

The new energy member companies of Fortune 500 companies cover fluorocarbon chemicals, fluorine-containing lithium battery materials, fluorine-containing special materials and fluorine-containing special chemicals. Relying on a complete scientific research system, stable industrial operation experience and an integrated operation mechanism of research, production and sales, it provides fluorine chemical products and solutions for more than 50 countries and regions around the world, and is a leader in the field of chemical hazardous waste.

![]()

In recent years, automation and intelligence have become the focus of the development and transformation of various industries. The traditional chemical hazardous waste field requires manual management, the efficiency is relatively low, and the management may not be in place. At the same time, hazardous chemicals have the characteristics of radiation, irritating odor, flammability, corrosiveness and explosiveness, which pose a certain threat to human health and safety. In this regard, when preparing for the construction of the chemical logistics park, the construction needs to realize the intelligentization of the logistics level and create a safer working environment were put forward.

![]()

In response to the customer's need to realize the intelligentization of the logistics level when preparing for the construction of the chemical logistics park, Megvii has planned an explosion-proof automatic logistics system to achieve intelligent management and logistics automation, improve production safety, and at the same time reduce employees from harsh , liberated from dangerous work environment.

![]()

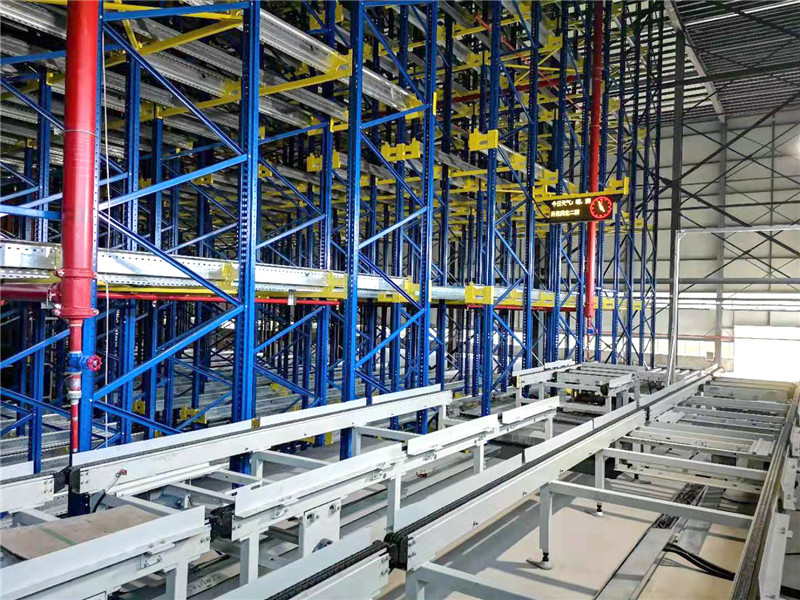

The project applies explosion-proof single-deep stacker, explosion-proof double-deep stacker and explosion-proof pallet conveying system, realizes the integration of complete explosion-proof automatic logistics system in hardware, and realizes the unified management of main warehouse + multiple sub warehouses in software.

The automatic transportation of hazardous chemicals can be realized through this solution, which can save human resources and liberate people from the work environment with certain hazards compared with traditional production lines. At the same time, the intelligent unified management of the warehouse is realized at the software level, which is more accurate than manual management and creates a safer production environment.

![]()

The fire protection level of this project is Class B for chemical hazardous wastes, and special explosion-proof design is adopted for automation equipment, electrical components, electrical cabinets, and power supply methods;

In addition, the industry adaptability adjustment is made to the operation speed of the equipment to ensure the safety of logistics and transportation;

Install explosion-proof cameras and other equipment above the logistics system, and use artificial intelligence technology to compare and manage the daily operation status of the warehouse, which can not only reduce a lot of traditional manual patrol work, but also avoid the inaccuracy of manual inspection and reduce accidents. probability of accident. At present, there are no more than 5 enterprises in the chemical and hazardous waste industry that have built explosion-proof automated logistics systems. This benchmark case provides a good reference for similar projects in the same industry. At the same time, leaders of relevant departments have organized groups to visit and give praises.