Entering the Guangzhou Logistics Center of Sinopharm Holding Guangzhou Co., Ltd. ("Sinopharm Guangzhou" for short), which has been upgraded with digital intelligence, it is already an intelligent scene - the main force of handling is autonomous mobile robots (AMR), stackers (AS/RS) and conveying line; the heavy depalletizing work is handed over to the AI robotic arm; the AI five-sided scanning device reads the electronic supervision code on the moving medicine box in real time, and realizes the traceability of drug circulation; operation In terms of management, the AI-based information system can display the operating status of equipment in real time and process business orders in a timely manner; the connected Gaotang warehouse and Kemulong warehouse are integrated to support the growing business traffic.

In this regard, Ma Jiancong, deputy general manager of Sinopharm Holding Guangzhou Co., Ltd., said: "This automated logistics center, which has been in production for more than 10 years, has achieved intelligent upgrades without delaying the normal operation of business for a day, and the overall efficiency of the warehouse has increased by 25%. With the ingenious design of dual warehouses and China Unicom and the leading Megvii 3A smart logistics solution (AS/RS+AMR+AI), the storage density of the logistics center has been increased by 15%, and the operation completion time has been advanced by 2 hours. Upgrading has a demonstration effect.”

Technology empowerment, exploring new directions for digital and intelligent upgrading

With the deepening of policies such as the two-invoice system and volume-based procurement, the cost pressure of pharmaceutical distribution companies has continued to rise. At the same time, the new retail of medicine has gradually become a trend, and the original supply chain operation mode has been difficult to adapt to the hugely changing market environment. Compared with ordinary commodities, medicines have higher requirements and more difficulty in quality management, and relying on traditional methods to improve the growth rate of inbound and outbound storage has slowed down significantly.

In 2020, 13 departments including the General Secretary and the National Development and Reform Commission have “encouraged enterprises to carry out intelligent transformation of logistics, promote the application of new technologies and equipment such as logistics robots, intelligent warehousing, and automatic sorting; coordinate and promote the construction of hardware and software of modern circulation systems”. Smart logistics has become a national key to promote internal circulation. Sinopharm Guangzhou is keenly aware that the transformation of digital intelligence has become the only way for the industry to create increments.

Sinopharm Guangzhou Automation Logistics Center has been put into operation for more than 12 years, the business volume has already increased several times, and the capacity has reached the ceiling. After multiple evaluations, on the basis of the original AS/RS automation system, the introduction of autonomous mobile robot AMR and AI technology to achieve digital and intelligent transformation is the optimal solution.

As a leading drug distribution and supply chain service provider in southern China, Sinopharm Guangzhou has always focused on the core measures of Sinopharm Accord's "Technology Empowerment Service Upgrade", aiming at the common difficulties and pain points in the pharmaceutical distribution industry, taking the lead in deploying digital intelligence and exploring innovative solutions. A non-stop, non-rebuild upgrade road. It is understood that 200 million drug sales need to be exported every working day in the Guangzhou Logistics Center of State Control, and a one-day shutdown will face huge economic losses and seriously affect the supply of drugs in Guangdong and Guangxi.

Therefore, after half a year of calculation and discussion in 2020, Sinopharm Guangzhou introduced the autonomous mobile robot AMR and AI technology developed by the world-class artificial intelligence company Megvii, and finally achieved a seamless upgrade without delaying business operations for a day. For enterprises that urgently need intelligent upgrade in the entire pharmaceutical distribution system, we have explored a feasible path to realize the upgrading of pharmaceutical logistics centers from automation to intelligence through digital and intelligent transformation.

AS/RS+AMR+AI, Megvii 3A Smart Logistics Solution

In response to the needs of Sinopharm Guangzhou to expand production capacity and to ensure the timeliness and service level of customer orders, Sinopharm Guangzhou has transformed the original single warehouse - traditional automated three-dimensional warehouse (AS/RS) + manual picking into double warehouses, AS/RS + AMR + AI works together, with the Megvii 3A smart logistics solution with high input-output ratio (ROI), high flexibility, high utilization rate, fast deployment and easy maintenance, which improves the overall efficiency of the warehouse by 25%, and the completion time of the operation is 2 hours earlier.

In AS/RS automatic storage and box picking, an AI robotic arm with visual recognition + intelligent control is applied to reduce the intensity of manual work and improve efficiency. There are 2000+ SKUs stored in the three-dimensional warehouse, and each SKU has different sizes and stacking types of goods, and there are many kinds of colors, top sealing strips, and packaging ties. According to reports, the daily box picking volume in the three-dimensional warehouse is about 6,000 boxes. In the original manual operation mode, the average daily load of workers is 30,000 kilograms. After the robotic arm with AI visual recognition capability, the efficiency of depalletizing and palletizing has been improved as a whole. 106%, greatly reducing the work intensity of workers.

In the shelf box picking process, it used to rely on people walking around the site for picking, and each person had to walk 30,000 steps per day. Now there are autonomous mobile robots (AMR) that carry shelves on their backs, line up and leave the warehouse. The whole process of goods-to-person (GTP) out of the warehouse is automated and intelligent. Even if the volume of goods is large, there is no need to worry about the operating distance. As a result, not only does the picker run less "half marathons" every day, but the efficiency has also been greatly improved.

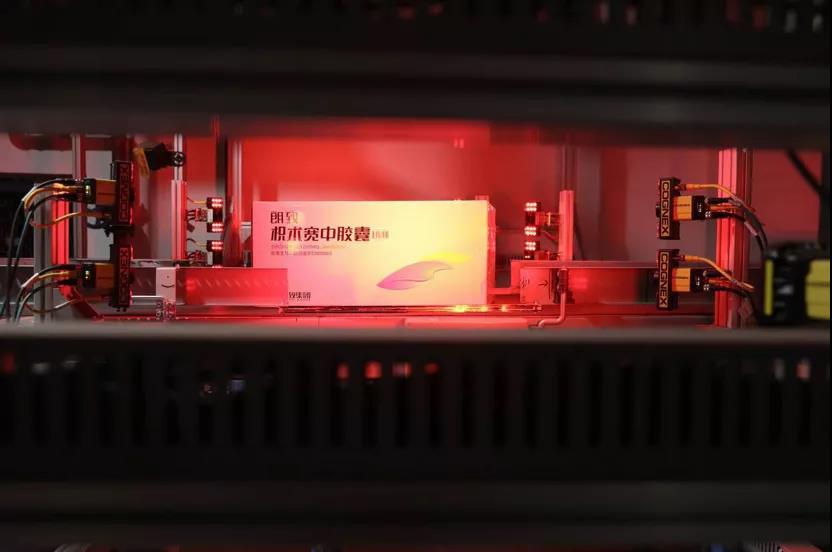

In addition, before the sorting process, Sinopharm Guangzhou warehouse adopts an AI five-sided visual scanning system, which can automatically scan and identify the original drug box in high-speed operation, read all the barcodes on the five sides of the front, rear, left, right and top, and pass them through. Effective filtering, binding the drug supervision code and the logistics code, and sending it back to the WMS system, on the one hand, realizes the rapid sorting of cartons, on the other hand, achieves transparency and traceability.

AMR robots, AI robotic arms, AI five-sided vision scanning systems, AS/RS stackers, conveyor lines and other diverse equipment in the warehouse are managed in a unified manner through the smart logistics operating system, and the WCS and WMS in the warehouse are connected. , RCS and other multi-layer equipment control systems to achieve efficient scheduling and management of the entire warehouse.

Tens of millions of economic benefits and technology, injecting support for the pharmaceutical circulation industry

Sinopharm's Guangzhou logistics center has been transformed to achieve capacity upgrades and fully automated operations. The capacity upgrade meets the current business needs, and at the same time, there is no need to increase the warehouse operation area, which saves the cost of warehouse leasing. It is estimated that after the project transformation, the average annual labor cost saving is over one million yuan, and it will save the state control Guangzhou in the next five years. Cost tens of millions of dollars. At the same time of cost saving, the successful launch and effective operation of the project will bring greater social benefits and industry demonstration effect.

At the moment when the epidemic situation is normalized, Sinopharm Guangzhou, as a central medical emergency reserve unit, its intelligent transformation will help to quickly respond to the needs of medical supplies distribution and help improve the service capabilities of primary medical institutions. Sinopharm Guangzhou's exploration in the field of smart logistics has improved its pharmaceutical logistics service capabilities, and will also promote the high-quality development of the health industry in Guangdong Province and even the whole country to a certain extent, and provide citizens with better and higher-level health services.

For the pharmaceutical logistics industry, Sinopharm Guangzhou's first intelligent transformation and upgrading project, which upgrades while operating, allows the industry to see the possibility of intelligent upgrading through different paths - it is not necessary to build a new warehouse or logistics center to move forward. Intelligent. This project has a strong demonstration effect on the pharmaceutical business field, and will effectively drive the pharmaceutical and intelligent logistics to further deepen the automation and intelligent transformation, and promote the high-quality development of the industry. In the future, Sinopharm Guangzhou will further explore the innovative model of pharmaceutical logistics, tap the value of AI in the field of medicine, and continue to copy the successful experience to more real industries that need intelligent transformation.

The introduction of AI in Sinopharm Guangzhou has opened up a new model of smart logistics. In the future, we will continue to uphold the corporate mission of "Caring for Life and Care for Health", fulfilling the responsibility of a central enterprise, and actively "building a leading international medical and health service platform". Relying on the Internet of Things, big data, artificial intelligence and other technologies, apply and develop more advanced and intelligent software and hardware systems and equipment. Utilize the advantages of Internet+ and Wisdom+ to promote the efficient operation of logistics and help Sinopharm Accord develop with high quality. In turn, it will promote the industry to accelerate the deep integration of technology and logistics, and drive the further development of the pharmaceutical logistics industry.

Source: World Wide Web